Market situation of electronic gases in semiconductor materials

The overall market situation of electronic gases in semiconductor materials shows a steady growth trend, especially with the rapid development of the global semiconductor industry, the demand for high-purity electronic specialty gases continues to increase. The importance of electronic gases in the semiconductor manufacturing process is self-evident, as they are widely used in the production processes of integrated circuits, flat panel display devices, solar cells, and other fields.

From the perspective of market demand and scale, according to TECHCET’s data, the global electronic gas market size in 2021 is about 6.25 billion US dollars, a year-on-year increase of over 7%, of which the electronic specialty gas market size is 4.53 billion US dollars. It is expected that by 2025, the global market size of electronic gases will exceed 8 billion US dollars. This reflects the strong demand for electronic gases in the global market. As one of the world’s largest semiconductor markets, China’s electronic specialty gas market has reached a scale of 21.6 billion yuan and is growing rapidly, with a compound annual growth rate of 15.96% from 2016 to 2021.

Market situation of electronic gases in semiconductor materials

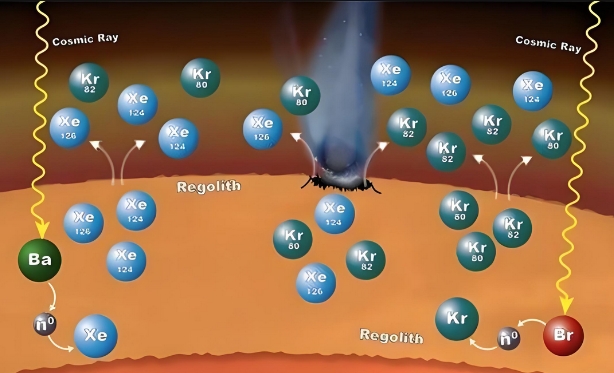

In terms of market structure and segmentation, the proportion of specialty gases and bulk gases is approximately 71.6% and 28.4%, respectively. Electronic specialty gases are mainly used in fields such as integrated circuits, liquid crystal panels, photovoltaics, LEDs, etc., especially in the semiconductor industry, accounting for up to 71%. These electronic specialty gases mainly include fluorinated specialty gases such as nitrogen trifluoride, tungsten hexafluoride, etc. These gases are widely used in the chip manufacturing process, for key processes such as etching and chemical vapor deposition.

The process of domestic substitution is accelerating. Domestic enterprises have gradually achieved the production of some key specialty gases through technological innovation and capacity expansion, thereby reducing external dependence. For example, nitrogen trifluoride and tungsten hexafluoride have basically achieved domestic substitution. This process not only improves the security of the domestic supply chain, but also reduces costs and enhances the market competitiveness of domestic enterprises.

Policy support is also an important factor in promoting the development of the electronic gas market. The country has introduced a series of policies to encourage and support the development of the electronic gas industry, especially focusing on the research and application of high-end chips, integrated circuit equipment, and process technology. These policies not only provide financial support for enterprises, but also provide guidance for industry standards and technological upgrades.

Despite the broad market prospects, the electronic gas industry still faces some challenges. Firstly, the technological barriers are high, requiring enterprises to have the production capacity of high-purity gases and strict quality control systems. Secondly, industry competition is becoming increasingly fierce, with international large enterprises dominating. Domestic enterprises need to continuously improve their technological level and market service capabilities to maintain their competitive advantage. In addition, market price fluctuations may also affect a company’s profitability.

In summary, the overall market situation for electronic gases in semiconductor materials is improving, with sustained growth in market demand, accelerated domestic substitution process, and increased policy support. However, in the face of technological barriers and market competition, enterprises need to constantly innovate and enhance their own strength to seize market opportunities and respond to challenges.